In a world where the only limit is imagination, selective laser sintering (SLS) 3D printing emerges as the superhero of manufacturing. With a laser-focused approach, it transforms powdered materials into solid masterpieces, making it possible to create everything from intricate prototypes to functional end-use parts. Forget about the days of waiting for your ideas to materialize; SLS is here to save the day—and your deadlines.

Table of Contents

ToggleOverview of Selective Laser Sintering 3D Printing

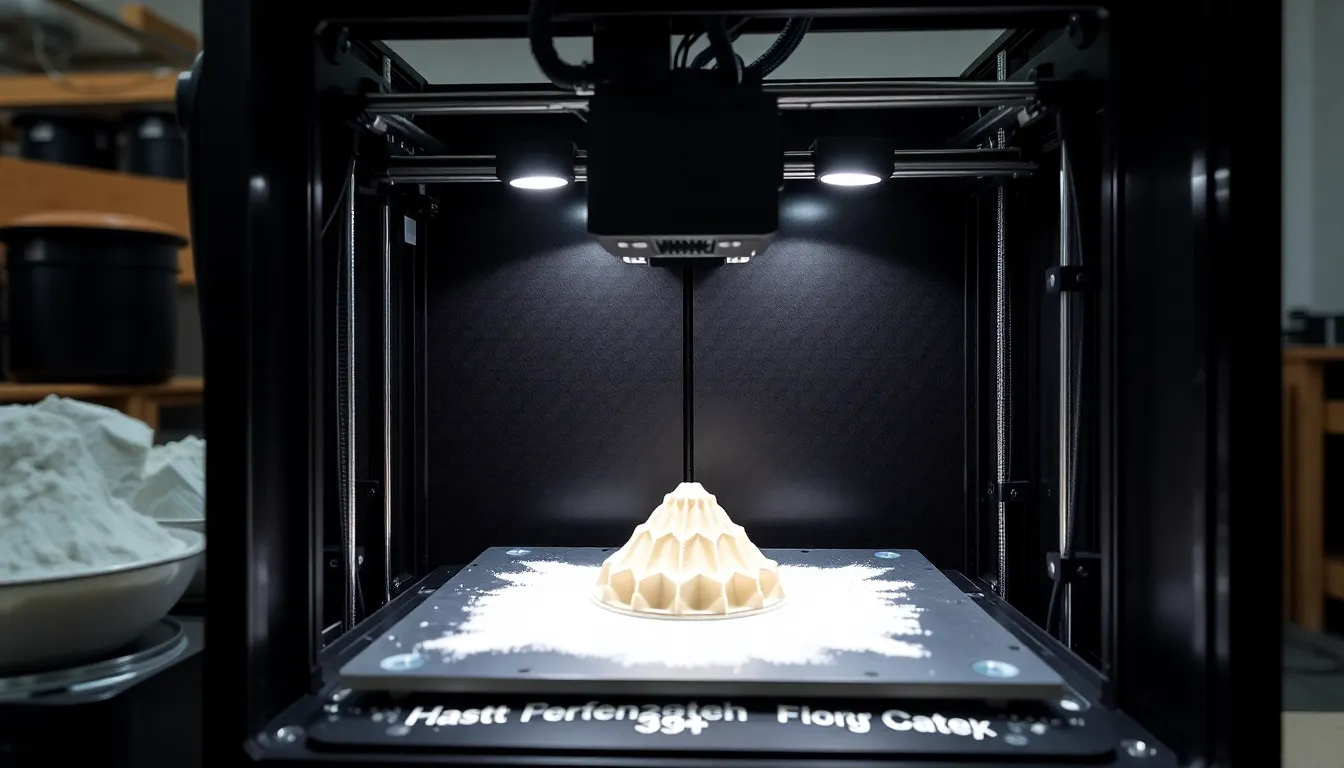

Selective laser sintering (SLS) 3D printing stands out for its unique capability to transform powdered materials into robust and intricate objects. This technique employs a laser to selectively fuse powder particles together, layer by layer, until the desired form emerges. Engineers frequently leverage SLS for producing high-precision prototypes and functional parts that withstand real-world conditions.

Common materials used in SLS include nylon, polyamide, and metal powders, which contribute to the versatility and strength of the final outputs. Each material offers distinct benefits, allowing designers to select based on specific project requirements. Customization remains a key advantage; SLS accommodates complex geometries that traditional manufacturing methods struggle to achieve.

Production efficiency is another significant attribute of SLS technology. The process minimizes waste by using only the necessary amount of powdered material, making it an environmentally friendly solution. Additionally, SLS allows for rapid iteration, enabling teams to test and refine designs quickly.

Cost-effectiveness plays a role in SLS’s popularity among businesses. Although initial setup costs for SLS printers can be high, the reduced waste, material efficiency, and speed of production often result in lower overall costs for large-scale projects. This balance of quality and economy makes SLS an appealing option for many industries.

Selective laser sintering 3D printing revolutionizes manufacturing with its ability to create detailed prototypes and functional end-use parts efficiently. By utilizing advanced materials and optimizing production processes, SLS continues to drive innovation across various sectors.

Advantages of Selective Laser Sintering 3D Printing

Selective laser sintering (SLS) 3D printing offers numerous advantages, making it a popular choice in various manufacturing sectors.

High Precision and Detail

High precision in SLS results from the laser’s ability to fuse powder layer by layer. Small features and intricate designs retain accuracy throughout the build process. Each layer solidifies without compromising the overall integrity of the object. Tolerance levels often reach ±0.2mm, suitable for both prototyping and production parts. Detail preservation consistently meets the needs of industries like aerospace and medical devices, where complex geometry is essential. SLS therefore plays an important role in achieving high-quality results across various applications.

Material Versatility

Material versatility stands out among SLS’s primary benefits. Designers can choose from a wide range of materials, including nylon, polyamide, and metal powders. Each material contributes distinct properties, catering to specific project requirements. For instance, nylon provides excellent strength and flexibility, while metal powders offer enhanced durability. SLS accommodates different applications by supporting both polymers and metals. This ability to work with various material types enhances customization, allowing teams to innovate and create tailored solutions. Thus, material selection plays a crucial role in maximizing performance and functionality.

Limitations of Selective Laser Sintering 3D Printing

Selective laser sintering (SLS) 3D printing offers numerous advantages, yet it has notable limitations that may affect its application in certain projects.

Cost Considerations

Initial investment in SLS equipment can be high, which influences accessibility for smaller companies. Alongside this, material costs associated with SLS are often greater compared to traditional methods. Businesses may face increased expenditures when acquiring specialized powders and maintenance for intricate machinery. Despite its long-term cost benefits, particularly for large-scale productions, upfront financial barriers can deter some users.

Production Speed

Production speed in SLS is another key consideration. Although SLS enables complex designs, the layer-by-layer process can slow down overall output. Each layer requires precise laser action, which may extend lead times for projects. Organizations needing rapid prototyping or high-volume outputs might find that SLS lacks the speed offered by other technologies, such as fused deposition modeling (FDM). This contrast highlights the necessity for careful planning regarding timelines in relation to project demands.

Applications of Selective Laser Sintering 3D Printing

Selective laser sintering (SLS) 3D printing finds extensive use across various industries due to its unique capabilities. Aerospace frequently employs SLS for producing lightweight yet robust components that meet stringent safety and performance standards. Medical device manufacturers utilize SLS technology to create patient-specific implants and surgical tools with high precision.

Automotive applications also benefit significantly from SLS. Designers create functional prototypes and end-use parts, enabling rapid testing and iteration. The customizability offered by SLS allows automotive engineers to optimize vehicle performance.

Consumer products leverage SLS for rapid prototyping, which accelerates product development cycles. Companies produce intricate designs that cater to specific consumer needs and preferences. Electronics manufacturers exploit SLS to create housings and components, effectively balancing functionality and aesthetic appeal.

The fashion industry explores SLS for creating unique accessories and wearable items. Designers utilize the technology’s potential to craft complicated patterns that enhance visual interest. Additionally, educational institutions incorporate SLS 3D printing in their curriculum, providing students hands-on experience with advanced manufacturing techniques.

Food manufacturing sees emerging trends with SLS as well. Customized molds and tools for food production benefit from the technology’s efficiency. Moreover, the ability to minimize waste aligns with sustainability goals pursued by many companies.

In architecture, SLS enables the creation of detailed models and prototypes. Architects visualize designs effectively, enhancing collaboration and communication with clients. The combination of speed and precision in SLS proves indispensable for showcasing complex structures.

SLS’s applications illustrate its versatility across sectors, making it a vital tool in modern manufacturing processes. With constant advancements, the technology continues to open new doors for innovation and design possibilities.

Selective laser sintering 3D printing stands at the forefront of manufacturing innovation. Its ability to create complex and durable components from powdered materials revolutionizes how industries approach design and production. The technology not only enhances efficiency but also promotes sustainability by minimizing waste.

With its adaptability across various sectors from aerospace to fashion SLS continues to drive advancements in product development. While challenges such as initial costs and slower output exist careful planning can mitigate these issues. As businesses increasingly recognize the benefits of SLS they unlock new possibilities for creativity and functionality in their projects. This technology is poised to shape the future of manufacturing in exciting ways.