In the world of 3D printing, selective laser sintering (SLS) stands out like a unicorn at a horse show. This innovative technology doesn’t just layer materials; it fuses them together using lasers, creating intricate designs that would make even the most seasoned artist green with envy. Imagine crafting complex parts with precision while sipping your morning coffee—SLS makes that dream a reality.

Table of Contents

ToggleOverview of Selective Laser Sintering

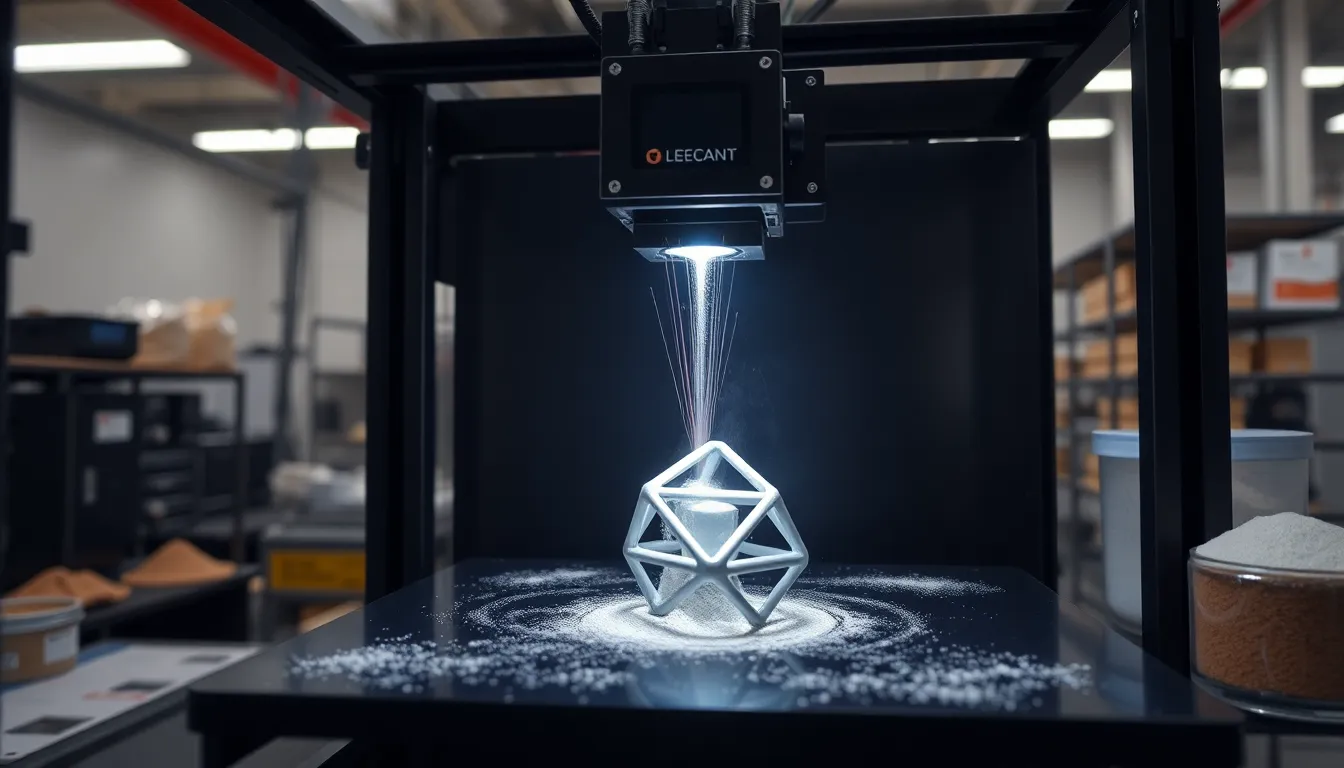

Selective laser sintering (SLS) represents an advanced additive manufacturing technique that significantly enhances design freedom. This process fuses powdered materials using a high-powered laser, which selectively melts and combines particles layer by layer. Multiple materials commonly used in SLS include polymers, metals, and ceramics, providing versatility in applications.

SLS benefits from the absence of support structures, which allows for the creation of complex geometries not achievable with other methods. The internal support usually found in traditional processes isn’t necessary, reducing material waste. As a result, designers can easily integrate intricate features and optimize part performance without constraints.

Dimensional accuracy in SLS typically ranges from 0.1 to 0.2 millimeters, making it suitable for functional prototypes and end-use parts. Process efficiency is notable; SLS machines can operate continuously, enabling production speed that traditional methods often lack. This efficiency proves advantageous for industries requiring rapid prototyping and small-scale production runs, such as aerospace and medical sectors.

Quality consistency is another notable aspect of SLS. The powder bed retains thermal stability, minimizing distortions during printing. Furthermore, the end products exhibit exceptional mechanical properties, often outperforming those produced with other additive manufacturing technologies.

Costs associated with SLS can vary based on material type, machine specifications, and production volume. However, the long-term savings in production efficiency and material conservation frequently justify the investment. Overall, SLS continues to evolve, cementing its role as a vital technology in modern manufacturing landscapes.

Process of Selective Laser Sintering

Selective laser sintering encompasses several key steps that contribute to its efficiency and effectiveness in 3D printing. Understanding these processes enables users to maximize the technology’s potential.

Material Selection

Material selection plays a crucial role in SLS. A variety of materials can be used, including nylon, polystyrene, and metals such as aluminum and titanium. Each material offers distinct properties that suit specific applications. Nylon, for instance, provides flexibility and durability, making it ideal for functional prototypes. Metals, on the other hand, deliver enhanced strength and thermal resistance, benefiting industries like aerospace and automotive. Users often choose materials based on their mechanical requirements and desired characteristics to optimize product performance.

Layering Technique

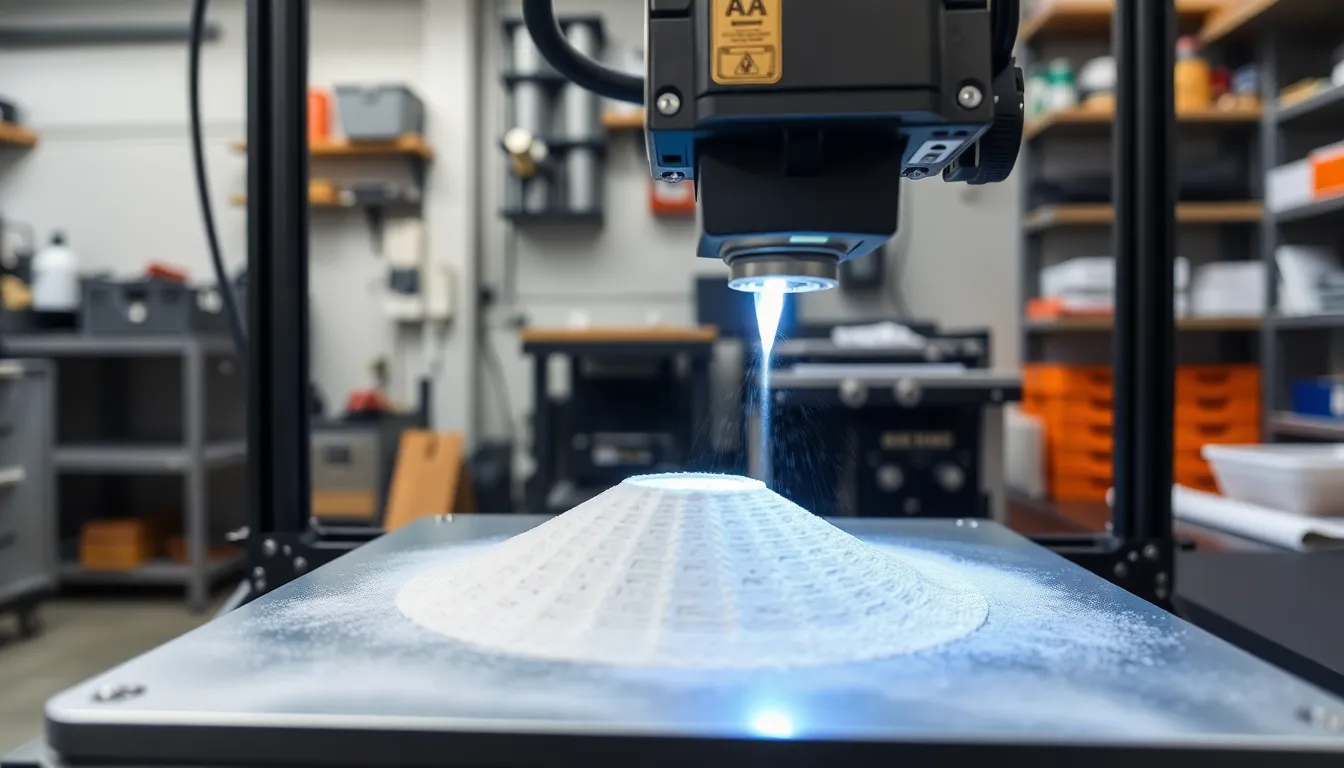

The layering technique in SLS involves applying a thin layer of powdered material onto a build platform. Lasers then selectively fuse the powder based on a 3D model. A process like this allows for precise control over the fusion of particles, resulting in accurate dimensions. After the laser completes one layer, the platform lowers, and another layer of powder is spread. This cycle continues until the entire object is formed. Such a method not only enables complex geometries but also eliminates the need for support structures. The effective layering ensures high-quality results with reduced material waste.

Applications of Selective Laser Sintering

Selective laser sintering (SLS) finds diverse applications across various industries due to its unique capabilities.

Industrial Use Cases

SLS is particularly advantageous in the aerospace industry, where lightweight, complex parts enhance performance and fuel efficiency. Manufacturers utilize SLS for creating components like brackets and housings that require precision and strength. In automotive production, companies leverage SLS for functional prototypes and tooling, allowing them to test designs rapidly. Medical devices, also benefit from SLS, enabling the production of customized implants and surgical instruments tailored to patient needs. The ability to produce small-batch parts with intricate geometries makes SLS a preferred choice for industries prioritizing innovation and efficiency.

Prototyping and Design

Prototyping with SLS streamlines the design process significantly. Designers create intricate models with few limitations on geometry. Rapid iteration becomes possible, allowing for quick adjustments that enhance functionality. Engineers appreciate SLS for its ability to produce durable prototypes that closely resemble final products. The technology also accommodates a wide range of materials, offering flexibility in design choices. By reducing time to market, SLS supports companies in maintaining competitive advantages while experimenting with new concepts. Overall, its role in prototyping fosters creativity and accelerates product development cycles.

Advantages of Selective Laser Sintering

Selective laser sintering offers numerous benefits that enhance its appeal as a modern manufacturing solution. First, the absence of support structures facilitates the creation of complex geometries without compromising design integrity. This capability reduces material waste significantly compared to traditional methods, resulting in a more sustainable approach.

Another notable advantage is the dimensional accuracy achievable with SLS. Producing components with precision tolerances ranging from 0.1 to 0.2 millimeters caters well to functional prototypes and end-use applications, ensuring quality and performance.

Rapid production speeds also distinguish SLS from conventional techniques. Continuous operation of SLS machines proves particularly advantageous for industries that demand quick turnaround times, such as aerospace and medical sectors. This feature allows businesses to meet tight deadlines while maintaining consistency and quality in outputs.

Mechanical properties of SLS-produced parts frequently exceed those created by alternative additive manufacturing methods. These components often exhibit greater durability, which contributes to their suitability for critical applications.

Material selection expands the versatility of SLS. Options include nylon, polystyrene, and various metals like aluminum and titanium, each providing unique attributes tailored to specific project requirements. The layering technique employed ensures that each component contains controlled fusion of particles, which reinforces the structural integrity of the finished product.

Customization represents another vital benefit. SLS is instrumental in producing tailored solutions, such as bespoke implants and surgical instruments. This adaptability not only meets specific client needs but also enhances overall product design.

Overall, selective laser sintering empowers industries to innovate by streamlining the design process while maintaining creative freedom. Rapid iteration and adjustments become possible, bolstering productivity and fostering competitive advantages in the marketplace.

Challenges and Limitations

Selective laser sintering presents certain challenges that can impact its effectiveness in various applications. High initial equipment costs can deter small businesses from investing in SLS. Energy consumption also raises concerns, as extensive power use during the printing process can lead to increased operational expenses over time.

Material limitations exist, as not all materials can be effectively processed through SLS. For instance, while polymers, metals, and ceramics perform well, some advanced composites may not deliver optimal results. Additionally, the quality of the final product often depends on the properties of the chosen material, creating a need for careful selection.

Print speed remains another factor to consider. Though SLS machines operate continuously, the overall speed may not match that of traditional manufacturing methods for large-scale production. Consequently, projects requiring rapid turnaround times might benefit from alternative techniques.

Post-processing requirements add further complexity. Often, SLS parts necessitate additional steps like cleaning and surface finishing to meet desired specifications. This extra labor can increase the time and cost associated with production.

Precision is crucial in SLS; minor inaccuracies can lead to significant functional issues. Dimensional tolerances typically range from 0.1 to 0.2 millimeters, but deviations may occur as a result of variations in material properties or printer settings. Manufacturers must maintain strict quality control to minimize these discrepancies.

Lastly, the importance of thermal management during the printing process cannot be overlooked. Poor thermal stability can lead to warping or distortion, negating the benefits of SLS technology. Addressing these challenges ensures that selective laser sintering remains a competitive and reliable solution in the evolving landscape of manufacturing.

Future Trends in Selective Laser Sintering

Emerging trends in selective laser sintering signal advancements in technology and materials. Increased adoption of sustainable materials like bio-based polymers aligns with environmental concerns. New developments in machine capabilities enhance print speeds while maintaining precision.

Advancements in AI and machine learning contribute to process optimization, allowing for real-time adjustments during printing. Integration of software solutions streamlines the design-to-manufacturing workflow, enabling greater efficiency. Collaborative robots, or cobots, support SLS by automating repetitive tasks and improving production rates.

Customization and personalization remain key drivers, with manufacturers tailoring products to specific customer requirements. Subscription-based access to SLS services is gaining traction, offering flexibility and reducing initial investment barriers.

Innovations in post-processing techniques facilitate smoother finishes and improved mechanical properties for final products. The introduction of multi-material printing capabilities allows for combinations of different materials within a single print run.

As marketplaces grow more competitive, businesses increasingly focus on reducing time-to-market for new products. Investment in training for skilled workers enhances competency in operating advanced SLS machines.

Future research may unlock new materials, expanding the applications of SLS into areas like electronics and functional components. Demand for faster prototyping cycles drives the exploration of hybrid manufacturing techniques that blend SLS with traditional methods.

Continuous advancements in thermal management technologies help to mitigate issues of warping and distortion during production. Organizations committed to innovation in selective laser sintering will likely benefit significantly from these emerging trends.

Selective laser sintering stands as a transformative force in the 3D printing landscape. Its ability to produce complex geometries without the need for support structures not only enhances design freedom but also promotes sustainability through reduced material waste. Industries ranging from aerospace to healthcare are leveraging SLS for its precision and efficiency, making it an invaluable tool for rapid prototyping and customized solutions.

As technology continues to evolve, SLS is expected to embrace new materials and innovations that will further enhance its capabilities. The integration of AI and automation will likely streamline processes, making SLS even more accessible and efficient. Organizations that invest in this technology will find themselves well-positioned to thrive in an increasingly competitive market.